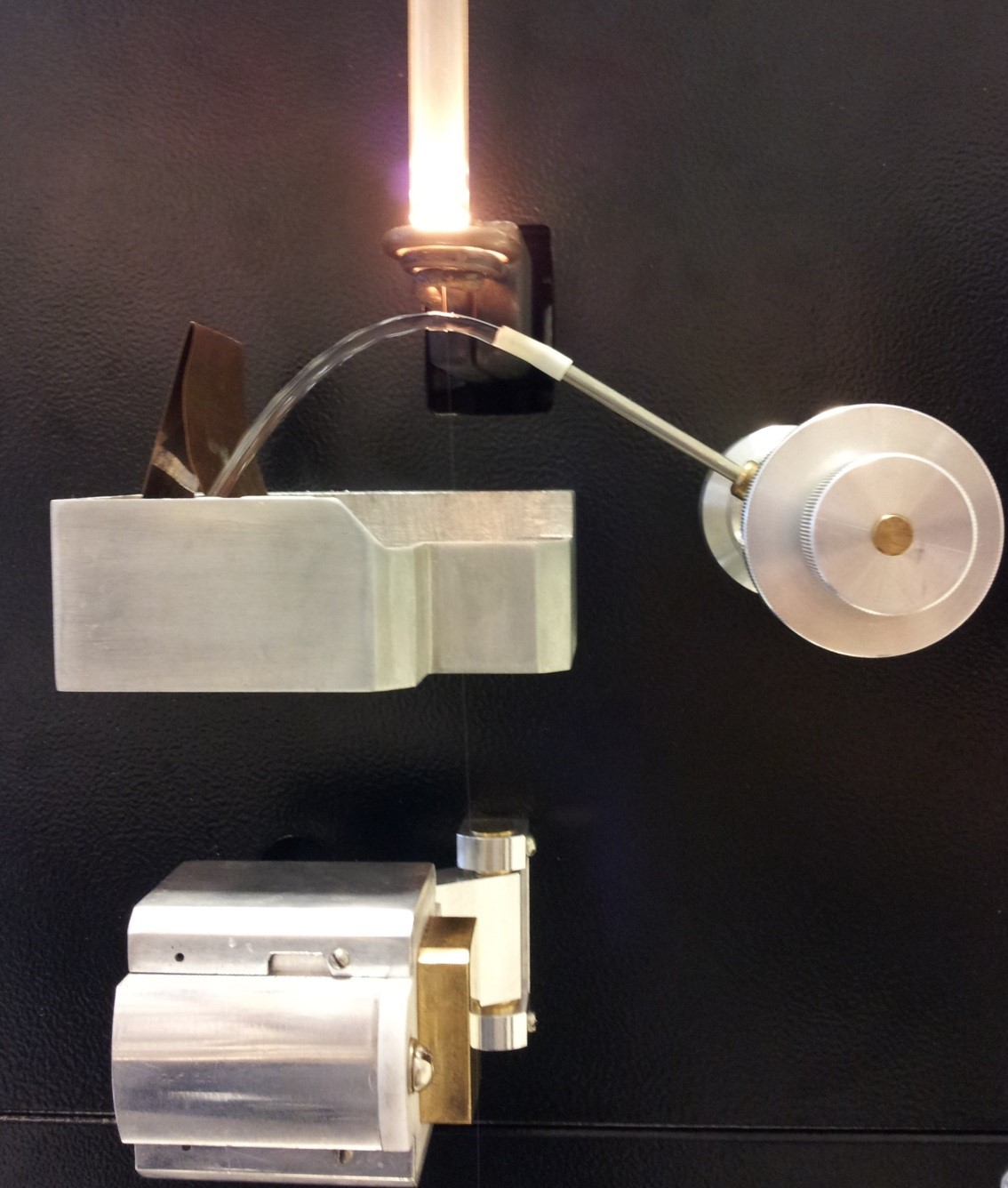

Machines for production glass-covered microwires

The metallic nucleus of microwire can be produced from:

- Pure metal: Ag, Au, Cu, Ni, Pt …

- Resistive Cu-Ni-Si-Mn, Ni-Cr-Si … composition alloys

- Magnetic amorphous Fe-B-Si, Co-Fe-B-Si, Co-Mn-B-Si …

- Composition alloys with:

- Natural Ferromagnetic Resonance (up to 8 GHz)

- Magnetic Bistable Behavior

- High Permeability at Frequencies up to 30 MHz

- GMI

The following metallic nucleus diameters can be obtained for:

| Cu, Ag, Au | 5 – 40 µm |

| Ni, Pt | 3 – 20 µm |

| Cu-based alloys | 2 – 25 µm |

| Ni-based alloys | 1 – 20 µm |

| Fe-B-Si based | 1 – 20 µm |

| Co-Mn-B-Si based | 3 – 25 µm |

| Co-Fe-B-Si based | 3 – 25 µm |

Technical characteristics:

The Installation is joined to three-phase 380 V power voltage of frequency 50 Hz. Microwire cooling liquid either water or oil. The Installation needs in cooling water. Consumption – not less then 10 l/min. Power supply is 10 kV×A. The HF power supply provides oscillating power 8 kV×A of frequency 440 kHz. The rate of microwire casting up to 500 m/min. The length of unbroken not less than 500 m.

Overall dimensions:

| casting modulus | 670 x 670 x 1800 mm |

| HF power source | 520 x 670 x 1800 mm |

Machines mass:

| casting modulus | 350 kg |

| HF power source | 300 kg |

Fabrication of Glass Coated Microwires.