General Information about Microwires

The microwire metal core may be produced from:

- Pure metal: Ag, Au, Cu, Ni, Pt etc.

- Resistive Cu-Ni-Si-Mn, Ni-Cr-Si etc. composition alloys

- Magnetic amorphous Fe-B-Si, Co-Fe-B-Si, Co-Mn-B-Si etc. composition alloys with:

- Natural Ferromagnetic Resonance

- Magnetic Bistable Behavior

- High Permeability at Frequencies up to 30 MHz

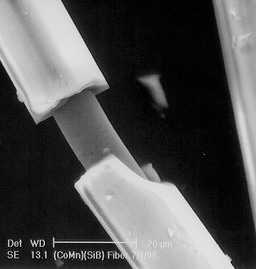

This is a microscopic view of an microwire (scale 1:1,000). You can select the material of the microwire example by standing with the mouse pointer on one of the materials or compositions listed above:

| Pure metal | Resistive | Magnetic |

| Ag (Silver) Au (Gold) Cu (Copper) Ni (Nickel) PT (Platinum) | Cu-Ni-Si-Mn Ni-Cr-Si | Fe-B-Si Co-Fe-B-Si Co-Mn-B-Si |

Developing quality microwires

In TAMAG we focus on developing quality microwires with innovative methods and researching their applications and properties, with the purpose of satisfying the needs of our customers worldwide.

Areas of application

Electronic industry:

- Microtransformers.

- Hielding of high frequency.

- Magnetic sensors of magnetic field.

Car and Aeronautic industry:

- Security and productivity of cables of high frequency.

- Heaters of windshield of cars and airships.

- Sensors of rotation of the motors, effectiveness of the brakes.

Protection of the environment to high frequency (mobile phone):

- Mobile phone industry.

- Health and environment institutions (Personnel in the airports).

Magnetic codification:

- SUPERMARKETS: labelled for products.

- TEXTILE: to introduce microwires in the labels to identify original products: the fraud or black market fights.

- LIBRARIES/VIDEOCLUBS: control of products.

- AIRPORTS: identification of people and baggage.

- SECURITY: magnetic keys, anticreep sensors.